“Mechanical Engineering” is a diverse and interdisciplinary field that touches virtually every aspect of modern life, from the cars we drive to the appliances we use and the buildings we inhabit. It requires a strong foundation in mathematics, physics, and engineering principles and creativity and problem-solving skills to tackle complex challenges and innovate new solutions.

Mechanical Engineering focus would be given to the design, analysis, manufacturing, and maintenance of mechanical systems. It encompasses a wide range of disciplines, including mechanics, thermodynamics, materials science, structural analysis, and electricity.

Key Intigrants of Mechanical Engineering

These specialized areas highlight the breadth and depth of mechanical engineering and its contributions to advancing technology, improving quality of life, and addressing global challenges. Mechanical engineers continually adapt to new technologies and interdisciplinary collaborations to drive innovation and progress in diverse fields.

Design:

Mechanical engineers design a variety of products and systems, ranging from small components like gears and bearings to large-scale machinery like engines and turbines based on principles of physics and mathematics. They would comply to create designs that meet specific performance, safety, and cost requirements.

Machine Design:

Machine design involves creating mechanical systems and components that perform specific functions efficiently and reliably. This includes mechanisms as well as the integration of the small components into larger systems. Engineers consider factors such as load-bearing capacity, fatigue resistance, and manufacturability during the design process.

Analysis:

Before a design is implemented, mechanical engineers have to conduct a thorough analysis to ensure its feasibility and efficiency. This includes mathematical modeling, simulation, and testing to predict how a system will behave under different conditions and loads.

Structural Analysis:

Mechanical engineers analyze the structural integrity of components and systems to ensure they can withstand the forces and stresses they will encounter during operation. This involves techniques such as finite element analysis (FEA) to predict how structures will deform and fail under various loads.

Manufacturing:

Manufacturing engineering focuses on optimizing the processes used to produce mechanical components and products. They aim to improve efficiency, reduce costs, and ensure product quality throughout the manufacturing process.

Mechanical engineers in this field work on aspects such as machining, casting, forming, and additive manufacturing (3D printing). Once a design is finalized, they oversee the manufacturing process to turn the concept into a tangible product. With the cooperation with machinists, technicians, and production engineers they choose the appropriate materials and manufacturing techniques.

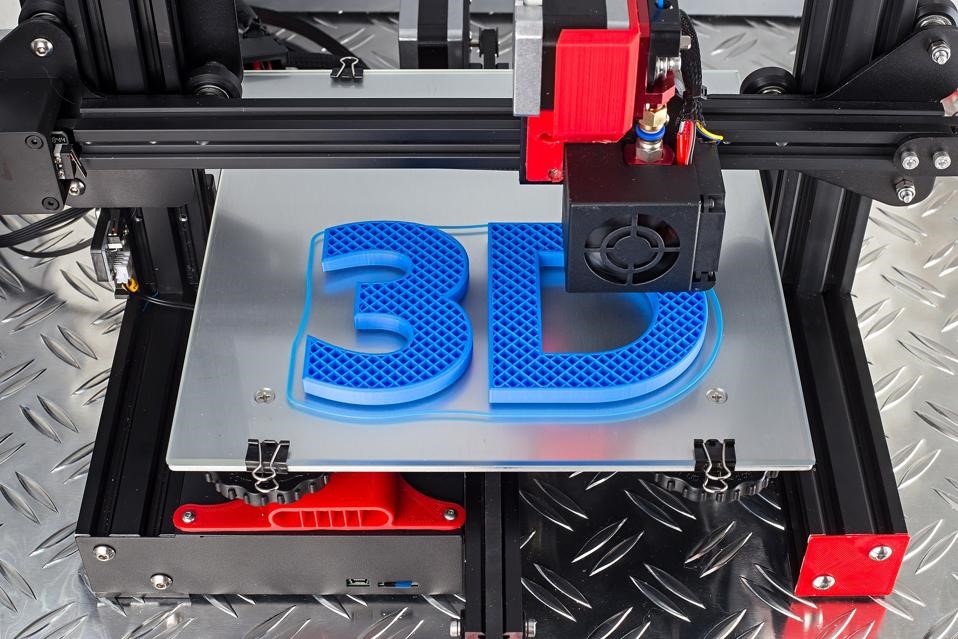

Additive Manufacturing (3D Printing):

Additive manufacturing, commonly known as 3D printing, has revolutionized the way mechanical components and prototypes are produced. Mechanical engineers leverage 3D printing technology to create complex geometries, lightweight structures, and customized parts with reduced material waste and lead times.

Thermodynamics:

Thermodynamics is a fundamental aspect of mechanical engineering, dealing with transferring heat and energy within systems. Mechanical engineers apply thermodynamic principles to optimize the performance of engines, HVAC systems, and thermal management systems.

Heat Transfer:

Heat transfer is essential for designing efficient thermal systems and managing temperature gradients in various applications. Mechanical engineers study conduction, convection, and radiation to develop heat exchangers, cooling systems, and thermal insulation materials.

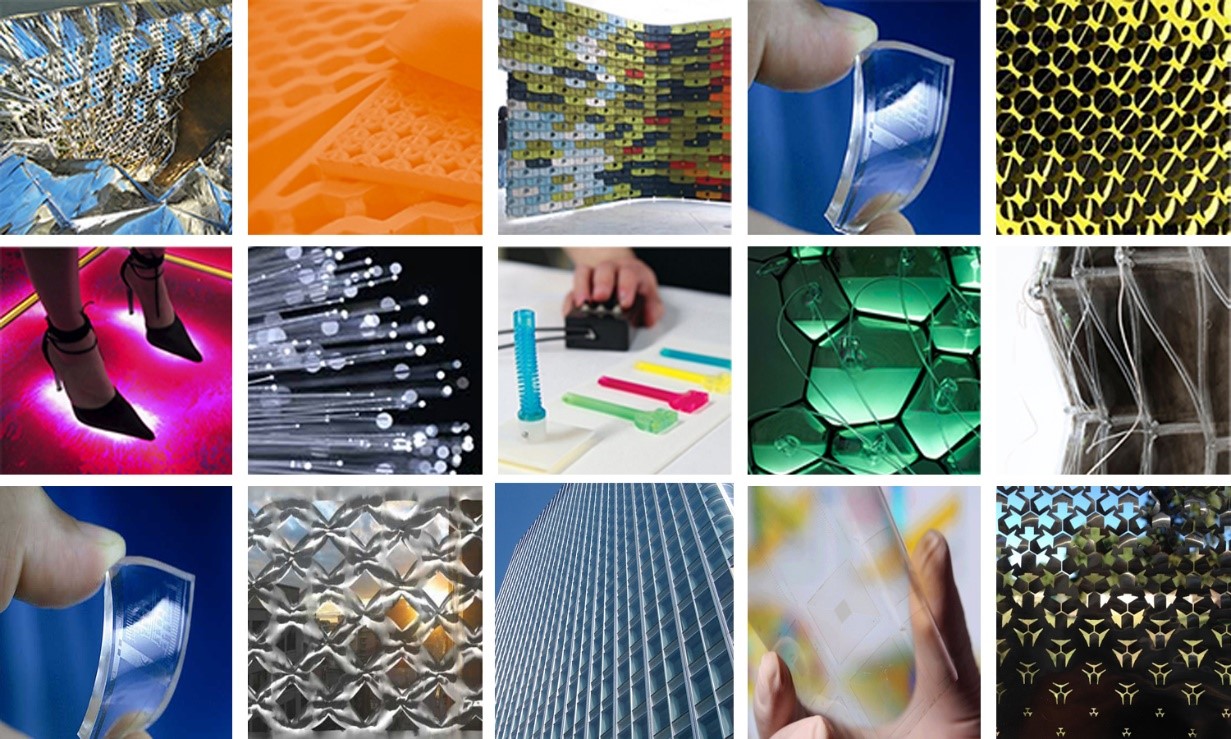

Materials Science:

Selecting proper materials for manufacturing is one of the most challenging tasks for mechanical engineers. Understanding the properties and behavior of materials is crucial in mechanical engineering. Engineers select materials based on strength, durability, thermal conductivity, and corrosion resistance to ensure that components can contend with operating conditions and environmental factors.

Smart Materials and Structures:

Smart materials have properties that can be altered in response to external stimuli such as temperature, stress, or magnetic fields. Mechanical engineers explore the use of smart materials such as shape-memory alloys, piezoelectric materials, and self-healing polymers in various applications, including adaptive structures, actuators, and sensors. These materials enable innovative solutions in fields like aerospace, robotics, and healthcare.

Electricity and Electronics:

Most of the modern machines often incorporate electrical and electronic components. Mechanical engineers may work alongside electrical engineers to integrate sensors, actuators, and control systems into mechanical designs.

Robotics and Automation:

Robotics and automation have become integral parts of many industries, from manufacturing to healthcare. Mechanical engineers design and develop robotic systems for tasks such as assembly, inspection, and material handling, improving efficiency and safety.

Automotive Engineering:

Mechanical engineering focuses on the design and development of vehicles, including cars, trucks, motorcycles, and off-road vehicles. Engineers work on aspects such as engine design, chassis development, aerodynamics, and vehicle safety. With the rise of electric and autonomous vehicles, automotive engineering is undergoing significant technological evolution.

Environmental Impact:

With growing concerns about sustainability and environmental conservation, Mechanical engineers play a crucial role in developing technologies that reduce energy consumption, minimize pollution, and optimize resource utilization.

Human Factors Engineering:

This is a branch of engineering that focuses on designing systems, products, and environments to optimize human performance, safety, and comfort. Mechanical engineers collaborate with psychologists, ergonomists, and designers to create user-friendly interfaces, ergonomic workstations, and accessible products. Human factors engineering is essential in fields such as transportation, healthcare, and consumer electronics.

Renewable Energy Systems:

With the growing emphasis on sustainability and combating climate change, mechanical engineers are playing a crucial role in the development of renewable energy technologies. This includes the design and optimization of wind turbines, solar panels, hydroelectric systems, and geothermal energy systems. Engineers in this field work to improve efficiency, reduce costs, and integrate renewable energy sources into existing power grids.

Fluid Mechanics:

Mechanical engineering also deals with the behavior of fluids (liquids and gases) and their interactions with solid structures. Fluid mechanics is crucial in designing systems such as pumps, turbines, pipelines, and HVAC (heating, ventilation, and air conditioning) systems. Engineers use principles such as conservation of mass, momentum, and energy to analyze and optimize fluid flow.

Computational Fluid Dynamics (CFD):

CFD involves using numerical methods and algorithms to simulate fluid flow and heat transfer phenomena. Mechanical engineers utilize CFD software to analyze and optimize designs of aerodynamic surfaces, HVAC systems, combustion processes, and more. CFD allows engineers to predict performance, identify potential issues, and refine designs without the need for physical prototypes, saving time and resources.

Aerospace Engineering:

Mechanical engineers contribute to the development of designing aircraft, spacecraft, propulsion systems, structural components, aerodynamics, and thermal management systems for aerospace vehicles. This field demands high precision, reliability, and safety standards due to the extreme conditions encountered in aerospace environments.

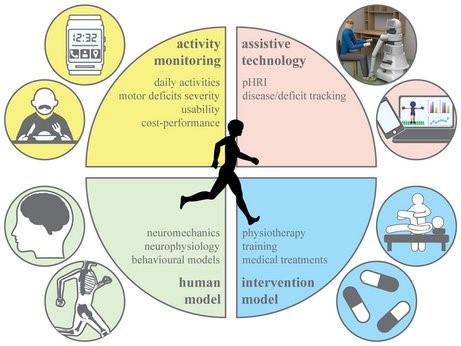

Biomechanics:

Biomechanics is a recently developed field that applies principles of mechanical engineering to understand the mechanics of biological systems, such as the human body. Mechanical engineers collaborate with medical professionals to design prosthetic limbs, orthopedic implants, and medical devices. They also study how forces and movements affect biological tissues and organs, contributing to fields like sports science and rehabilitation engineering.

Nanotechnology and Micro-electromechanical Systems (MEMS):

Nanotechnology involves manipulating materials and devices at the nanoscale (atomic or molecular level), while MEMS focuses on miniaturized mechanical and electromechanical systems. Mechanical engineers contribute to the design and fabrication of nanomaterials, nanosensors, and MEMS devices for applications such as biomedical implants, environmental monitoring, and consumer electronics.

Internet of Things (IoT) and Cyber-Physical Systems (CPS):

Mechanical engineers contribute to the development of IoT-enabled systems and cyber-physical systems that integrate mechanical components with digital technology. This includes smart buildings, industrial automation, wearable devices, and intelligent transportation systems.

Join Ken Institute’s online courses in Mechanical Engineering, Occupational Health and Safety, Fire Safety, Environment and Sustainability.

These are just a few examples of the diverse applications of mechanical engineering. The field continues to evolve as new technologies emerge, creating opportunities for innovation and interdisciplinary collaboration across various industries.

To delve in deep and elevate your Mechanical Engineering expertise! Join Ken Institute and unlock a world of online courses in Mechanical Engineering, Occupational Health and Safety, Fire Safety, and Environment and Sustainability. Propel your career to new heights.

Get in touch with us at: info@keneducation.in

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.