The manufacturing industry is always evolving, requiring manufacturers to quickly respond to industry change and make a strong commitment to efficiency in every aspect of business to stay competitive. The development of an “Advanced Manufacturing Process” involves the creation, refinement, and optimization of a production method that incorporates cutting-edge technologies and innovative techniques to improve efficiency, quality, and productivity in manufacturing. This process is often aimed at enhancing product design, streamlining production workflows, and reducing costs while maintaining high-quality standards.

Advanced Manufacturing Process refines existing products and performs production activities that will improve the quality and process of manufacturing to give manufacturers a competitive edge.

Advanced manufacturing is a more sophisticated type of manufacturing typically and more closely associated with industries than traditional manufacturing, which is based on the use of dedicated plant and production lines with little to no flexibility.

Advanced Manufacturing Process mainly includes:

- Artificial intelligence

- Machine learning

- Digital twin

- Robotics and automation

- Additive manufacturing

- Nanotechnology

- Advanced materials

- Network and connectivity (IoT)

- Laser machining

Each of these advanced manufacturing processes plays a valuable part in helping manufacturers work more safely and efficiently.

Industries Utilizing Advanced Manufacturing Techniques

Industries currently at the forefront of advanced manufacturing include:

- Automotive

- Pharmaceuticals & Medical Devices

- Consumer Products

- Electronics & High-Tech

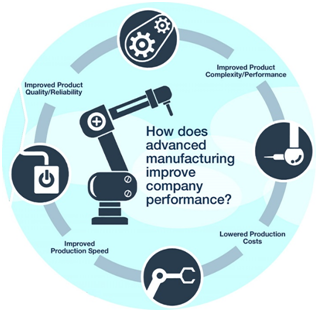

Benefits of Advanced Manufacturing Processes

Regardless of industry, advanced manufacturing techniques prove valuable in many ways. Top benefits include:

- Improved product quality – The precision, consistency, and overall efficiency of advanced manufacturing processes lead to product quality that is more reliable, available, and affordable.

- Smarter resource management – Advanced manufacturing aids in leaner production efforts by automating manufacturing tasks so personnel can focus on more innovative projects.

Reduced production timelines – The flexibility and optimized planning and scheduling involved in advanced manufacturing allow for better market responsiveness.

- Innovation – When manufacturing efforts are more automated and cost-effective, resources can be more focused on research and development, allowing for new and exciting goods to be brought to market.

A detailed overview of the development process:

Research and Analysis:

- Conduct comprehensive research to identify the current manufacturing processes and their limitations.

- Analyze market trends and technological Advanced Manufacturing Processes to understand the innovation potential.

- Identify the specific needs and requirements of the target industry or product.

Conceptualization and Planning:

- Develop a clear vision and set specific goals for the advanced manufacturing process.

- Brainstorm and conceptualize innovative ideas that can address the identified limitations and improve production efficiency.

- Create a detailed plan outlining the steps required to achieve the goals, including timelines and resource requirements.

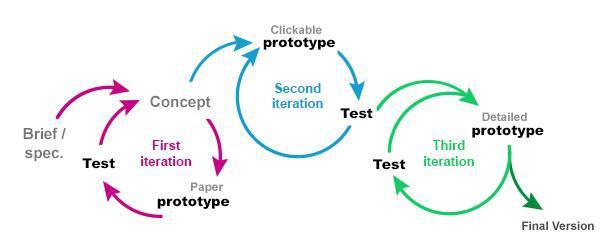

Prototype Development:

- Build a prototype of the advanced manufacturing process to test its feasibility and functionality.

- Conduct thorough testing and evaluation to identify any potential issues or areas for improvement.

- Gather feedback from stakeholders and industry experts to refine the prototype.

Integration of Advanced Technologies:

- Incorporate advanced technologies such as robotics, automation, artificial intelligence, and IoT (Internet of Things) to streamline the production process.

- Implement advanced materials and techniques that can improve product quality and performance.

- Integrate data analytics and predictive maintenance systems to optimize production and minimize downtime.

Optimization and Scalability:

- Continuously optimize the manufacturing process based on real-time data and performance metrics.

- Conduct rigorous testing and analysis to ensure the reliability and scalability of the process for large-scale production.

- Identify opportunities for cost reduction and efficiency enhancement while maintaining high product standards.

Quality Control and Standardization:

- Implement robust quality control measures to ensure that the products meet the required standards and specifications.

- Establish a standardized production workflow and documentation process to maintain consistency and traceability.

- Conduct regular audits and inspections to identify and address any deviations or non-conformities.

Training and Implementation:

- Provide comprehensive training to the manufacturing workforce to familiarize them with the new processes and technologies.

- Ensure that the employees have the necessary skills and knowledge to operate and maintain the advanced manufacturing equipment.

- Monitor the implementation process closely and provide support to address any challenges or issues that arise during the transition.

Continuous Improvement and Innovation:

- Foster a culture of continuous improvement and innovation within the organization.

- Encourage feedback from employees and stakeholders to identify opportunities for further optimization and enhancement.

- Stay updated with the latest advancements in manufacturing technology and regularly evaluate the process to incorporate new improvements and features.

Conclusions

Advanced Manufacturing Process involves progressive research and development, labor skill, scaling, and dynamic and flexible production,

increasing output while optimizing value, quality, market responsiveness, and flexibility. Advanced manufacturing also aims to reduce time to market, material inventory, and content and unit quantities. With digital manufacturing on the rise, the adoption of advanced manufacturing is essential to the success of manufacturers.

Throughout the development of an advanced manufacturing process, it is crucial to prioritize collaboration, interdisciplinary teamwork, and a holistic approach to ensure the successful integration of advanced technologies and methodologies into the production environment. This approach can lead to increased efficiency, enhanced product quality, and a competitive edge in the industry.

“Join Ken Institute for comprehensive Mechanical Engineering Courses led by expert faculty, ensuring your readiness to tackle workplace fire emergencies effectively.”

To expand your perception around Mechanical Engineering & the health and safety topic, join us at info@keneducation.in or visit our website www.keneducation.in, or call +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.