Mechanical engineering first emerged during the Industrial Revolution. The technology we’ve developed and the skills of the engineers in the field have evolved dramatically with the emerging “Mechanical Engineering Trends” since then. The world is shifting toward a digital future. Mechanical engineers need to augment their existing skills or learn new ones, such as programming as mechanical engineering trends, increase in popularity. Their foundational experiences will continue to support many industries through 2024 and beyond.

Let’s see, what “Mechanical Engineering Trends” are set to shape the field well into the future? What will mechanical engineering look like in 2024 and beyond?

Mechanical engineering plays an important part in every aspect, from the construction of vehicles to facilities at home or work, directly or indirectly, in every facet of our lives.

Blending the Mechanical and Digital

AI, robots, and additive manufacturing will probably be the key technology propelling all engineering specialties over the next decades, software and electrical engineers cannot often implement their concepts without the assistance of mechanical engineers.

This increase in multidisciplinary engineering promises well for the employment outlook of mechanical engineers. However, it will need an industry-wide expenditure on continuous learning, from recent graduates to mid-career technicians to senior experts.

Here are some of the technologies that are boosting the field of Mechanical engineering:

Growth of Additive Manufacturing / 3D Printing

Additive manufacturing, known colloquially as 3D printing, is reshaping manufacturing practices globally with the push toward creating sustainable materials and flexible systems for on-demand 3D printing.

The global 3D printing market is expected to be worth more than $51 billion by 2030. The field will continue to grow beyond 2023, as additive manufacturing has become a valuable tool to build spacecraft for space travel and may continue to do so as we work to colonize the Moon, Mars, and beyond.

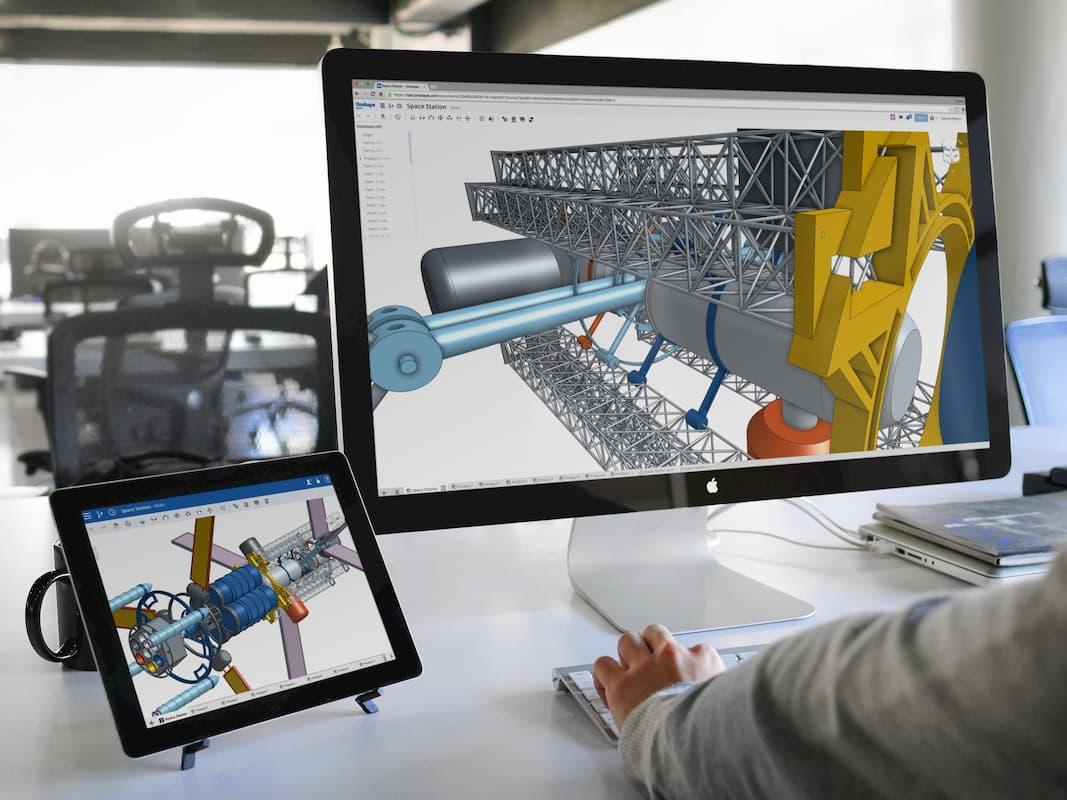

New Uses for CAD

Computer-aided design or CAD is a system that mechanical engineers have used for decades. Instead of just using it for design, it has become a tool for everything from performance simulations and stress tests to generative design and digital twinning.

Engineers will find unique new ways and new applications for newer CAD versions in the coming years.

Adopting Digital Twin Technology

Engineers often find themselves drowning in prototypes and physical models while making small changes to the design. Digital twinning is gaining popularity as a tool to reduce the number of physical prototypes necessary to complete a project. A digital twin is a virtual model that accurately represents an item in the physical world.

The digital twin can be equipped with virtual sensors, allowing mechanical engineers to put their products through stress and performance tests without creating a new prototype for each test. All the information collected in the digital space can be used to perfect the twin in the physical world.

Green Engineering

Sustainability has been a buzzword on the tip of everyone’s tongue in recent years. Countries are looking for new and innovative ways to reduce their CO2 emissions and carbon footprint to reduce its CO2 emissions by 40% before 2030. They also need to reach the goal of net zero emissions before 2050.

Mechanical engineers looking for a change could consider shifting to the more eco-friendly fields like Eco-engineering. Even without that career shift, there is a growing movement for engineers to create and embrace the kind of green engineering technologies that will move to reshape the industry in the coming decades.

Smart System and Automation

Automation is another facet beginning to heavily influence most engineering and manufacturing sectors. Automation is becoming a valuable tool for taking over tedious, monotonous, or dangerous tasks in the field.

Instead of putting a human worker at risk, an automated system can complete the same job. The robotics necessary to implement these systems fall firmly in the mechanical engineering sector.

Applications for IoT (Internet of Things)

The Internet of Things is growing exponentially. Beyond the smart technology that people are installing in their homes lies the Industrial Internet of Things. By connecting physical objects to the internet, engineers can monitor and control their systems remotely, allowing them to make more informed decisions and reduce downtime. Future IoT-enabled intelligent gadgets that can connect with the original equipment manufacturer (OEM) after leaving the production line are anticipated to increase.

Installing IoT systems relies heavily on communication between old machinery and new sensors. Mechanical engineers will need to work with other teams to improve IoT adoption in the workplace in the coming years.

Robotics

Robotics are becoming increasingly sophisticated and capable of performing complex tasks, and have a major impact on of accuracy and efficiency of building machines. Robotics can be used to automate tasks, to create new materials and components, improve existing processes and components, to perform surgery.

The most important is that robotics can be used to explore hazardous environments. They can learn and adapt to their environment, making them more efficient and effective.

Artificial Intelligence (AI)

AI is the ability of machines to learn, reason, and act like humans. AI can be used to automate processes, as well as to create new materials and components. AI is already used in mechanical engineering to improve the efficiency. It can help to identify potential problems and suggest solutions before they become a problem.

AI-powered robots are being used to develop autonomous vehicles, which can drive themselves.

Nanotechnology

Nanotechnology is the manipulation of matter on an atomic or molecular scale. It has the potential to create materials and components with unprecedented, strength, flexibility, and durability.

Nanotechnology can be used to create more efficient components and more efficient and sustainable manufacturing processes that require less energy to operate.

Computer-Aided Engineering

CAE software reduces the engineering process’s time and cost while improving the design’s quality by providing engineers with more accurate and detailed information about their designs.

In the future, CAE tools will become even more powerful and sophisticated. This will allow engineers to design more complex and intricate components and systems. CAE tools will be able to automate more of the engineering process, reducing the need for manual labor and improving the engineering process’s efficiency.

Transition of Combustion Engines

The transition of engines will undoubtedly significantly influence the mechanical engineering industry. One of the most substantial changes would be the gradual transition from combustion engines to battery-based systems. These seem far cleaner and less harmful to the environment.

As the electric vehicles (EVs) market expands, there will be a greater need for mechanical engineers. Moreover, they can forecast and manage how heat travels around a vehicle and how components and geometries react to pressures. Mechanical engineers can design the EV’s electrical control systems. With the growth of (EVs), mechanical engineers will have various new opportunities.

Pandemic-Fuelled Digital Transformation

The mechanical engineering sector was already on track to undergo a digital transformation before the Corona pandemic started in 2020. An assessment found that 67% of surveyed manufacturers accelerated their digital timetable because of the pandemic. It also forced to increase in the strength of remote work platforms. These platforms became valuable tools throughout the pandemic as many companies switched to remote teams to keep everyone safe from the virus.

Those remote platforms have continued to support workers moving through 2022 and will likely continue to do so throughout the coming years.

Conclusion

With the development of new technologies and the increasing demand for more efficient and sustainable products, mechanical engineers will continue to be at the forefront of innovation.

To learn more about similar topics, we are here to help you. Ken Institute provides courses exclusively for working Mechanical and OHSE Professional Engineers to up-skill their careers.

Join us at info@keneducation.in

visit our website at www.keneducation.in

call +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.