Mechanical engineering is an intricate blend of principles that provide the framework for engineering marvels. The Core Principles that apply in Mechanical engineering are the principles of physics, mathematics, and material science to design, analyze, manufacture, and maintain mechanical systems. These principles and tools form the foundation of mechanical engineering, enabling engineers to design, analyze, and improve systems and products that are crucial to everyday life.

Here, we explore the most important Mechanical Engineering Core Principles in detail

Mechanics and Forces: Exploring Motion and Equilibrium

Mechanics, the branch of physics concerned with motion and the forces that cause it, forms the cornerstone of mechanical engineering. Forces—be they gravitational, frictional, or reactive—are the agents that initiate movement, and their equilibrium keeps objects at rest. From the machinery that powers factories to the vehicles that navigate our roads, mechanics, and forces underpin the physical dynamics of these systems.

Key Concepts: Statics, which focuses on systems in equilibrium, and dynamics, which delves into motion and acceleration.

Kinematics

Kinematics: Focuses on the geometry of motion without considering the forces that cause the motion. It involves the study of velocity, acceleration, and displacement of particles and rigid bodies.

Key Topics of Kinematics: Linear Motion, Rotational Motion, Relative Motion, and Equations of Motion.

Thermodynamics:

Thermodynamics is the science of heat, work, and internal energy transformations. The laws of thermodynamics involve energy conversion processes, and the behavior of gases, liquids, and solids under various thermal conditions. It applies to systems ranging from engines to power plants, refrigeration, and air conditioning systems.

Key Concepts: First Law of Thermodynamics, Second Law of Thermodynamics, and Heat Engines and Refrigeration Cycles.

Heat Transfer

Focuses on the movement of heat in and out of systems through conduction, convection, and radiation. It’s essential in designing cooling systems, engines, and HVAC systems. Heat transfer focuses on the movement of heat (thermal energy) in systems, which is essential in many mechanical engineering applications, including engine cooling, HVAC design, and thermal management in electronics.

Key Concepts: Conduction (Fourier’s law), Convection, and Radiation (Stefan-Boltzmann law).

Fluid Mechanics:

Examines the behavior of fluids (liquids and gases) and their interactions with solid boundaries. Key concepts include fluid statics, fluid dynamics, and the Bernoulli equation. Fluid mechanics involves the study of liquids and gases in motion and at rest. It’s essential for understanding how fluids behave under different conditions, which is critical in designing pumps, turbines, hydraulic systems, and even aircraft.

Key Concepts: Fluid Dynamics, Fluid Statics, and Laminar and Turbulent Flow

Materials Science

Involves understanding the properties of materials and how they can be manipulated to create more efficient and durable products. This includes studying metals, polymers, ceramics, and composites. Study of systems with inputs and outputs, where feedback is used to maintain the desired output. This includes understanding system stability, controllers, and sensors. Materials science involves understanding the properties of materials (metals, ceramics, polymers, and composites) and how they can be used and altered to meet specific engineering requirements.

Key Concepts: Material Properties, Phase Diagrams, and Failure Mechanisms

Mechanics of Materials:

Concerned with the behavior of solid materials under various stresses and strains. This includes concepts like elasticity, plasticity, and failure theories. This area studies how materials deform under various types of loading (tension, compression, shear, torsion, and bending) and how these deformations affect the material’s strength and durability.

Key Concepts: Stress and Strain, Elasticity and Plasticity and Failure Theories

Dynamics and CAD, form the backbone of the discipline, enabling engineers to design, analyze, and produce complex mechanical systems efficiently.

Dynamics:

Dynamics concerns with bodies in motion. It includes both kinematics (the study of motion without regard to the forces that cause it) and kinetics (the study of forces and torques that cause motion).

Key Concepts of Dynamics: Newton’s Laws of Motion, Energy Methods, Impulse-Momentum, Damped and Undamped Oscillations.

Statics and Dynamics:

Statics: This branch of mechanics deals with bodies that are at rest or move at a constant velocity (i.e., in equilibrium). The primary focus is on understanding how forces are distributed within and on bodies. Engineers use statics to analyze structures like bridges, buildings, and other non-moving systems to ensure they can support loads without collapsing.

Key Concepts of Statics: Force Equilibrium and Free-Body Diagrams.

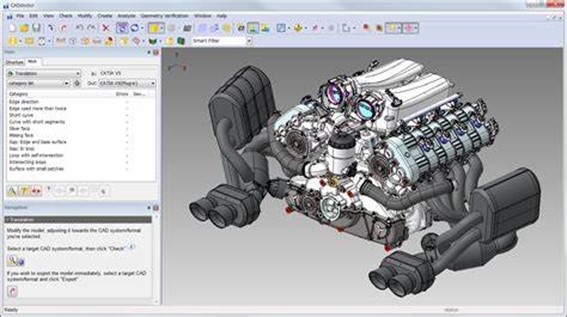

Computer-Aided Design (CAD)

Computer-aided design (CAD) refers to the use of computer systems to assist in the creation, modification, analysis, and optimization of a design. CAD software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and create a database for manufacturing.

Key Aspects of CAD:

- CAD is a technology used extensively in mechanical engineering to create precise drawings and models. It has revolutionized the design and manufacturing processes by providing detailed visualizations, simulations, and easy modifications to designs.

- 2D CAD: Involves creating flat, two-dimensional drawings of objects. This is often used for schematics, floor plans, and technical drawings where only length and width are important.

- 3D CAD: Allows for the creation of three-dimensional models of objects, providing a comprehensive view of the object’s shape, volume, and potential interference with other parts. 3D models are essential in modern engineering for creating parts that fit together perfectly in an assembly.

- Solid Modeling: Used to create a complete 3D representation of an object, including volume and mass properties.

- Surface Modeling: Focuses on defining the external contours and surfaces of a part, often used in automotive and aerospace industries for aerodynamic designs.

- Parametric Design: This allows the user to define the dimensions and shapes of the design based on parameters. When one parameter changes, the entire model can adjust accordingly.

- Simulation and Analysis: CAD software often integrates simulation tools that allow engineers to test and analyze designs under real-world conditions before physical prototypes are made. This can include stress analysis, thermal analysis, fluid dynamics, and motion studies.

- Finite Element Analysis (FEA): A computational method used to predict how a part or assembly behaves under various conditions, such as mechanical stress, vibration, heat, and fluid flow.

- Computational Fluid Dynamics (CFD): Simulation of fluid flow, heat transfer, and associated phenomena, often used in aerodynamics, HVAC, and other fluid-related fields.

- Manufacturing Integration: CAD files can be directly used in Computer-Aided Manufacturing (CAM) software to guide the machinery in producing the designed parts.

- Rapid Prototyping: CAD models can be used to create physical prototypes using 3D printing and other additive manufacturing technologies, allowing for quick testing and iteration.

- Documentation: CAD software is also used to generate the detailed technical drawings and specifications needed for manufacturing, including dimensions, tolerances, materials, and assembly instructions. These documents are essential for communicating design intent to manufacturers, ensuring that parts are produced accurately and to specification.

Control Systems

Control systems engineering involves designing systems that maintain desired outputs despite changes in inputs. This is crucial for automation, robotics, and manufacturing processes.

Key Concepts: Feedback Systems, PID Controllers, and System Stability

Conclusion

The Core principles of mechanical engineering, Dynamics provide the tools to understand and predict the motion of systems, while CAD offers the technology to visualize, simulate, and optimize designs before they are physically realized. Together, these tools and principles allow for the development of everything from simple mechanisms to complex machines and systems, pushing the boundaries of what’s possible in engineering.

Make Your Mark on Modern Industry

To gain the advanced acumen and skills needed to make your career stand out, join Ken Institute. Take advantage of the expert faculty’s vast research experience and the flexibility of 100% online learning.

Get in touch with us at: info@keneducation.in

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.