“Engineering Disasters” often arise from shortcuts in the design process. Engineering is the science and technology used to meet the needs and demands of society. To meet society’s demands, the creation of newer technology and infrastructure must be met efficiently and cost-effectively. To accomplish this, managers and engineers need a mutual approach to the specified demand at hand. This can lead to shortcuts in engineering design to reduce costs of construction and fabrication. Occasionally, these shortcuts can lead to unexpected design failures.

Engineering Disasters due to Mechanical Errors can lead to catastrophic events across various domains, from transportation to industrial accidents.

Here are some most notable Engineering Disasters that traumatized the world.

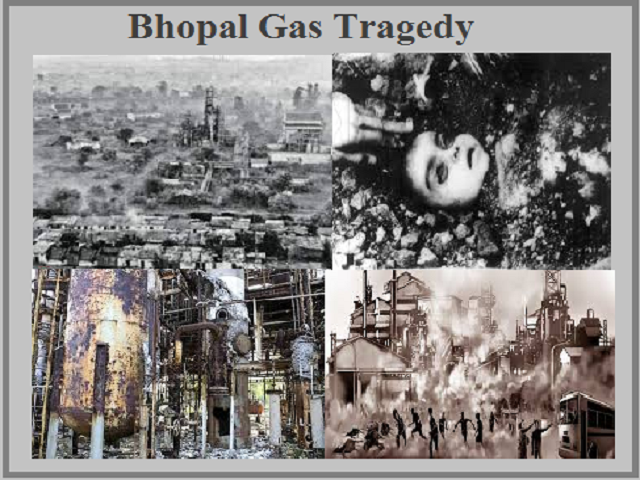

Bhopal Gas Tragedy (1984)

The Bhopal Gas Tragedy occurred on December 2-3, 1984, when a pesticide plant owned by Union Carbide Corporation leaked methyl isocyanate gas into the surrounding residential areas of Bhopal, India. The leak was caused by a combination of factors, including poor maintenance, inadequate safety measures, and a series of procedural and operational errors. The incident was primarily attributed to poor maintenance, inadequate safety measures, and a lack of proper emergency protocols.

The exact cause of the initial gas release remains disputed, but it led to thousands of immediate deaths and left hundreds of thousands suffering from long-term health effects, such as respiratory issues, neurological disorders, and birth defects.

Chernobyl Disaster (1986)

One of the worst nuclear accidents in history, the Chernobyl disaster was caused by a combination of flawed reactor design and operator error during a safety test. The reactor exploded, releasing a significant amount of radioactive material into the atmosphere, leading to widespread contamination and long-term health effects.

The Chernobyl disaster occurred at the Chernobyl Nuclear Power Plant in Ukraine. During a late-night safety test on April 26, 1986, the reactor experienced a sudden power surge, leading to a series of explosions that destroyed the reactor core and released radioactive material into the atmosphere. The explosion was caused by a combination of reactor design flaws and operator errors during the test, including the disabling of safety systems. The fallout from the disaster had severe environmental and health consequences, with thousands of immediate deaths and long-term health effects for millions due to radiation exposure.

Space Shuttle Challenger Disaster (1986)

The Space Shuttle Challenger exploded 73 seconds after lift-off, resulting in the deaths of all seven crew members. The disaster was traced back to the failure of an O-ring seal in one of the shuttle’s solid rocket boosters, which was exacerbated by cold weather conditions.

The cause of this Engineering Disaster was the failure of the primary and secondary redundant O-ring seals in a joint in the shuttle’s right solid rocket booster (SRB). The record-low temperatures on the morning of the launch had stiffened the rubber O-rings, reducing their ability to seal the joints. Shortly after liftoff, the seals were breached, and hot pressurized gas from within the SRB leaked through the joint and burned through the aft attachment strut connecting it to the external propellant tank (ET), then into the tank itself. Both SRBs detached from the now-destroyed ET and continued to fly uncontrollably until the range safety officer destroyed them.

Space Shuttle Columbia disaster (2003)

On Saturday, February 1, 2003, Space Shuttle Columbia disintegrated as it reentered the atmosphere over Texas and Louisiana, killing all seven astronauts on board. It was the second Space Shuttle mission to end in disaster, after the loss of Challenger and its crew in 1986.

During launch, a piece of the insulating foam broke off from the Space Shuttle’s external tank and struck the thermal protection system tiles on the orbiter’s left wing. Similar foam shedding had occurred during previous Space Shuttle launches, causing damage that ranged from minor to near-catastrophic, but some engineers suspected that the damage to Columbia was more serious.

Before reentry, NASA managers had limited the investigation, reasoning that the crew could not have fixed the problem if it had been confirmed. When Columbia reentered the atmosphere of Earth, the damage allowed hot atmospheric gases to penetrate the heat shield and destroy the internal wing structure, which caused the orbiter to become unstable and break apart.

Buncefield Oil Depot Explosion (2005)

A series of explosions occurred at the Buncefield oil storage depot in the UK, resulting in a large fire and significant damage to surrounding areas. The incident was attributed to a combination of factors, including the overfilling of a storage tank due to a malfunctioning level sensor.

The Buncefield oil depot explosion occurred on December 11, 2005, at the Hertfordshire Oil Storage Terminal in the UK. The explosion was caused by the overfilling of a storage tank, which released a large quantity of petrol vapor that ignited, resulting in a series of explosions and a massive fire. The overfilling occurred due to a malfunctioning level sensor, combined with human error in failing to respond to the initial alarms promptly. The incident led to significant damage to the facility and surrounding areas, as well as environmental concerns due to the release of pollutants into the atmosphere and groundwater.

Deepwater Horizon Oil Spill (2010)

The Deepwater Horizon oil spill is regarded as one of the largest environmental disasters in world history. An explosion on the Deepwater Horizon drilling rig in the Gulf of Mexico led to the largest marine oil spill in history. This devastating Engineering Disaster occurred due to a series of mechanical and operational failures, including the failure of a blowout preventer to contain the oil flow.

The Deepwater Horizon oil spill occurred on April 20, 2010, in the Gulf of Mexico, following an explosion on the Deepwater Horizon drilling rig operated by BP. The explosion was caused by a series of mechanical failures, including the failure of a blowout preventer to seal the well after a sudden release of high-pressure methane gas. The subsequent fire on the rig led to its collapse and the uncontrolled release of oil from the wellhead, resulting in the largest marine oil spill in history.

Fukushima Daiichi Nuclear Disaster (2011)

Following a powerful earthquake and tsunami in Japan, multiple reactors at the Fukushima Daiichi Nuclear Power Plant experienced meltdowns, hydrogen explosions, and the release of radioactive material. Mechanical failures in backup systems, such as cooling pumps and generators, contributed to the severity of the incident.

The Fukushima Daiichi nuclear disaster occurred in Japan on March 11, 2011, following a powerful earthquake and tsunami. The disaster led to meltdowns in three of the plant’s reactors, hydrogen explosions, and the release of radioactive material into the environment. Mechanical failures, such as the loss of cooling systems and backup power generators, contributed to the severity of the incident, highlighting vulnerabilities in the plant’s design and emergency preparedness.

Titan, a submersible explosion (2023)

On 18 June 2023, Titan, a submersible operated by the American tourism and expeditions company OceanGate, imploded during an expedition to view the wreck of the Titanic in the North Atlantic Ocean off the coast of Newfoundland, Canada.

After the submersible had been missing for four days, a remotely operated underwater vehicle (ROV) discovered a debris field containing parts of Titan.

Titan’s Pressure hull collapsed due to enormous water pressure. The failure is believed to have occurred because of the experimental design of the vessel’s hull. Unlike traditional materials, Titan’s hull was primarily made of less durable and less understood carbon fibers.

The incident resulted in the instantaneous deaths of all five occupants aboard the submersible. Authorities conducted search and rescue operations, but unfortunately, there were no survivors.

Titan operated in international waters and did not carry passengers from a port, it was not subject to safety regulations. The vessel was not certified as seaworthy by any regulatory agency or third-party organization.

Along with advancements sometimes come failures, be it in design, insufficient knowledge, or under or over-estimations. While sometimes catastrophic and deadly, engineers need to learn from failure. These Engineering Disasters highlight the importance of robust safety measures, thorough maintenance protocols, and effective risk management strategies to prevent mechanical errors from escalating into catastrophic events.

To gain the advanced acumen and skills needed to make your career stand out, join us; for online Mechanical Engineering, Health, Safety & Environment, Fire Safety, and Environment and Sustainability courses. Take advantage of the expert faculty’s vast research experience and the flexibility of 100% online learning.

Get in touch with us at: info@keneducation.in

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect together on Facebook, YouTube, LinkedIn, and Instagram.